Rotomolding and blow molding are probably the most constrain-free technologies for plastic transformation available today. Creativity is the only limit for giving shape to your ideas!

We offer quality and technical solutions in terms of tolerances, reliability and durability, that make us an efficient supplier in the most demanding sectors, like Automotive. Rototech is IATF 16949 certified.

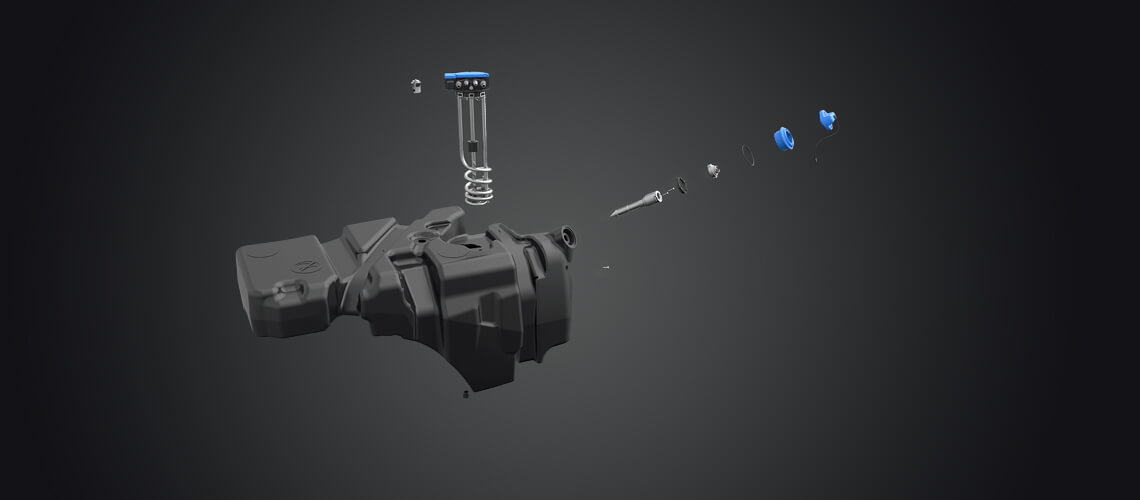

In the past decades Rototech created a full catalogue of components to be able to meet any requirement and provide tailor-made, fully integrated solutions by leveraging several technologies: rubber injection molding, plastic injection molding, metal and sheet metal stamping.

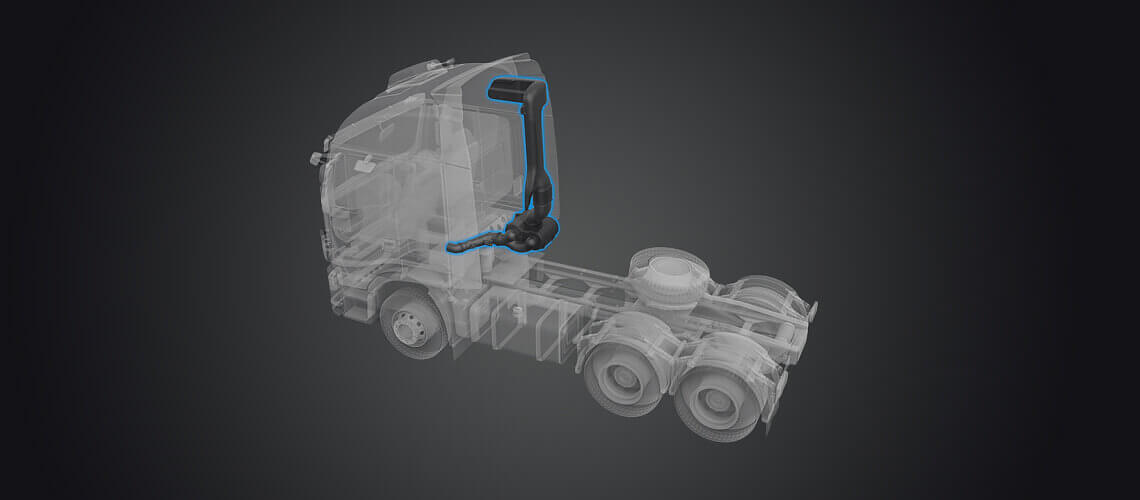

Rototech develops and produces cutting-edge engine pipe solutions for power units applications, combining tradition, multitechnology mindset and strive to take innovation to the next level.

Mold your ideas through plastic

Rotational and blow molding offer quality and technical characteristics in terms of tolerances, reliability and durability, that make these technologies the best choice in various sectors, like automotive, industrial, infrastructure, furniture, design, etc.

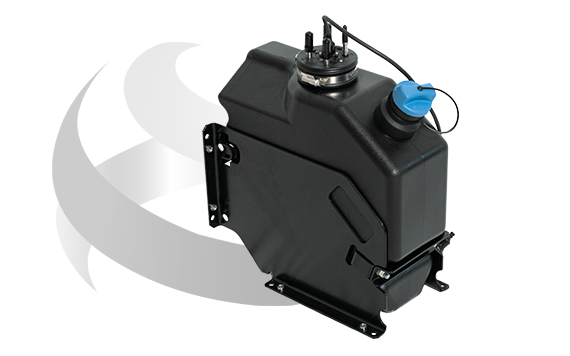

Tanks

Body Parts

Power unit components

Air intake system

Components

Energy Storage

Material Handling

Co-design

It is a huge privilege and responsibility for us to be considered by our customers as a strategic partner for the design and production of integrated systems that require innovative, quality-oriented and multitechnology mindset and competences. Due to our background, that roots back in sheet metal stamping, we have always been naturally inclined in developing and supplying complete solutions based on plastic rotational molding parts. The value of the expertise in co-design is hard to underestimate when it comes to metal to plastic conversion, as well as the benefits of the conversion itself: cost, weight and noise reduction, better mechanical resistance and resistance to chemicals, elimination of welding operation during the production phase. With rotational molding you can obtain a more complex shape, using every available space on a vehicle, thus gaining volume capacity, aerodynamics or layout optimization.